Oilfield technology advances exponentially: Apache Corp., PBPA, TIPRO report myriad innovations

February 7, 2024

Odessa American

by Bob Campbell

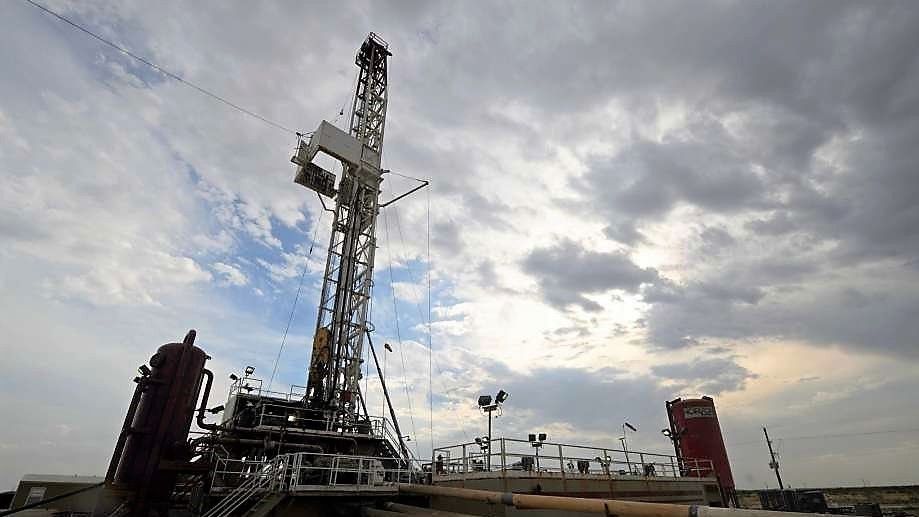

Attendees walk through the outdoor displays at the Permian Basin International Oil Show on its opening day Tuesday, Oct. 19, 2021, at the Ector County Coliseum. (OA File Photo)

The energy industry was quick to join the technological revolution in the 1980s and before and it has applied its brainpower and resources to more than keep pace since then.

The Apache Corp. and the Permian Basin Petroleum and Texas Independent Producers & Royalty Owners associations say the United States and the world have benefited as a result.

“At Apache, we focus on delivering top operational performance,” an Apache spokeswoman said from Houston. “Over the last three years we have made significant strides to more efficiently and responsibly extract hydrocarbons including the elimination of routine flaring across U.S. onshore operations.

“We achieved our lowest total recordable incident rate in 18 years, increased our safety observation rate and actions by 10 percent, reduced methane emissions across U.S. onshore operations by converting more than 2,000 pneumatic devices to instrument air or through valve retrofit and utilized at least 50 percent recycled produced water.”

The spokeswoman said that was all achieved during ramped-up production.

“Operating efficiencies and strong well performance across the Permian Basin led to a 16-percent increase in year-over-year oil volumes in the third quarter of 2023 from the third quarter in 2022,” she said. “Additionally Apache has focused on increasing the average lateral length of fracks from just over 10,000 feet in 2022 to closer to 10,500 feet in 2023.”

PBPA President Ben Shepperd said it’s amazing that the industry is producing hydrocarbons from source rock.

“If you’re asking what we are doing today that we could have only dreamed of a few decades ago, that’s what it would be,” Shepperd said. “That in itself is something that would have been unimaginable a few decades ago.

“But the mechanical technology we are using to develop those resources isn’t new. Horizontal drilling and hydraulic fracturing have been around for a long time. The first commercially successful use of hydraulic fracturing was in the 1950s and the first recorded true horizontal well was drilled in the Permian Basin in the late 1920s outside of Texon in Reagan County.”

Shepperd said the refinement of those processes, thanks in large part to modern day computing abilities, “is what really makes the development of source rock possible.

“The use today of computers to develop resources, map and maintain well paths and calculate the most effective and efficient fracture treatments are tools we couldn’t utilize without the modern-day microprocessor,” he said. “Microprocessors, computing power and overall connectivity, available because of that computing power, have all allowed for the utilization of remote working as well.”

Shepperd said working remotely has probably not enhanced the ability to produce source rock, “but producing resources from source rock and working remotely are only possible because of the incredible growth in computers.

“Even though computing power has helped the industry make tremendous progress in the way we do business and even with the growth of artificial intelligence, we still need folks in the field to conduct operations and adjust those operations as conditions change,” he said. “Further, whether it be in the field, in an office or working remotely, we need people making decisions on administrative and executive questions.

“The long and the short of it is that computers help us do our jobs, but the people element is still vital to our success.”

TIPRO President Ed Longanecker said from Austin that the oil and gas industry has long been at the helm of technology and innovation.

“Through this innovation operators in the Permian Basin have made incredible strides forward in the last decade from reducing methane intensity to its lowest point during record production to implementing new technologies that modernized operations,” Longanecker said from Austin. “Importantly, our industry would not be able to make these leaps forward if it weren’t for the dedicated and essential workforce that has remained resilient in challenging environments and the record-breaking global energy demand that we are successfully meeting.”

Citing carbon capture and direct air capture initiatives, he said Texas’ extensive network of existing pipelines, infrastructure and a workforce experienced in operational and technical demands, major companies like Occidental, Chevron, ExxonMobil and Kinder Morgan are investing in new CCS and DAC projects in the state, “finding ways to utilize existing infrastructure and environment to develop and safely deploy new technologies that will drive emissions even lower.

“Innovation in water management practices and fracking fluid chemistry has allowed Texas operators to re-use millions of gallons of produced water, even water with very high salinity, for fracking operations,” Longanecker said. “In fact, water in the Permian Basin is re-used by operators, reducing the use of freshwater supplies.

“Because of the reduction in water use, oil and gas production accounts for only 2 percent of the state’s total water consumption.”

Quoting the Ernst & Young professional services partnership, he said 92 percent of oil and gas companies are investing in artificial intelligence or are planning to do so in the next 5 years.

“Optimizing exploration and drilling while also streamlining production and logistics, the industry reports progress in efficiency, safety and sustainability,” Longanecker said. “Recent geopolitical issues in the Middle East and Ukraine are heightening concerns for not only energy security but also cybersecurity as threats to critical infrastructure increase.

“As the industry becomes more digitally integrated and faces increased threats, investments in cybersecurity are being prioritized to safeguard operations, infrastructure and the surrounding environment.”

As part of a wider effort to cut emissions during operations, he said, drillers in the Permian Basin are moving away from diesel-powered generators to fuel their operations and machinery and connecting to power grids.

“Because operations on a well pad demand high volumes of power, often more than a traditional grid can supply, operators are choosing to invest in their own microgrids built specifically to supply power for their operations,” Longanecker said. “Microgrids also create an opportunity to put flared gas to use rather than let the excess fuel burn off.”

Dating at least to the 1980s, he said, the oil and natural gas sector has turned to supercomputers to process large amounts of data.

“Most recently, major producers like British Petroleum’s Center for High-Performance Computing in Houston and the Eni Corp.’s HPC4 supercomputer in Milan, Italy, are processing 100,000 reservoir models in approximately 15 hours,” he said.

“From robotic tank inspectors to Smart Pigs to record information about the internal conditions of pipelines to gas cloud imaging, drones, machine learning and real-time communication across equipment through the Internet of Things, oil and gas companies are investing in technologies to improve safety and production efficiency, reduce emissions and more accurately determine where resources are located.”